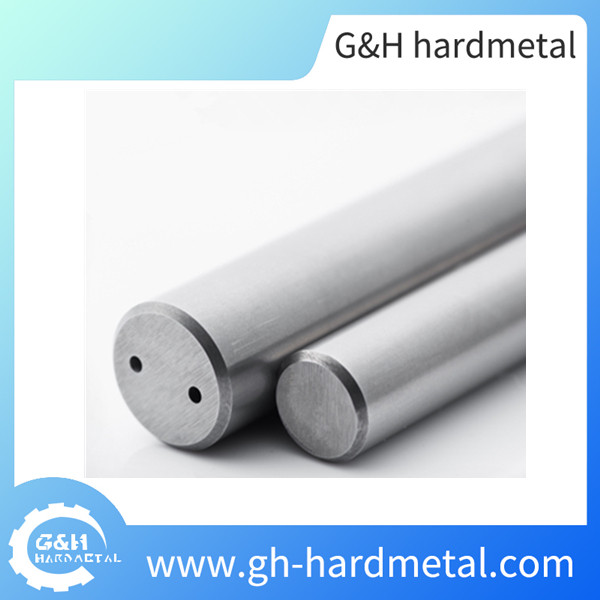

Micrograin Coolant Hole Rod

- group name

- Tungsten Carbide Rods

- Min Order

- 1 piece

- Delivery clauses under the trade mode

- FOB, CIF, EXW

- Acceptable payment methods

- T/T, L/C, PayPal, Westem Union

- update time

- Mon, 30 Sep 2019 14:39:11 GMT

Paramtents

Description Micrograin Coolant Hole Rod

Type Blank rods or ground h6

Specification Standard 1.2~32or Customized

Main Grade GH10 and GH12

Shape Solid Cylinder carbide

Feature Good Wear Resistance, HIP Sintering, long lifespan

Material 100% Virgin Raw Material

Packing Plastic tube +5 layer outer carton

Packging & Delivery

-

Min Order1 piece

Briefing

10% Coablt carbide rods recommanded for making drill, endmill, burr, specially for cutting non-ferrous metal and graphite.

Detailed

Grade Introduction

| Grade | ISO | Grain size (μm) | Cobalt Content (%) | Hardness (HRA) | Density (g/cm3) | T.R.S (N/mm2) |

| GH10F | K05-K10 | 0.4 | 6 | 93.5 | 14.8 | 3800 |

| Ultrafine grain size, with amazing wear resistance. High wear resistance endmill and engraving tools are recommended suitable for cutting PCB and composite material. | ||||||

| GH15F | K10-K20 | 0.4 | 8.5 | 93 | 14.52 | 3800 |

| Ultrafine grain size,with good wear resistance. High wear resistance endmill and engraving tools are recommended suitable for cutting PCB and plastic. | ||||||

| GH25F | K20-K40 | 0.4 | 12 | 92.5 | 14.10 | 4200 |

| Ultrafine grain size, higher Co content, with excellent hardness and toughness. Endmill and reamer are recommended. Excellent performance for finishing. Especially suitable for cutting steel ( HRC: 45-55 ) ,AI alloy and Ti alloy. | ||||||

| GH6A | K15 | 1.0 | 6.0 | 92.5 | 14.95 | 2450 |

| Drill, endmill and burr are recommended. Especially suitable for cutting non-ferrous metal and graphite(coating is needed). | ||||||

| GH20 | K20-K40 | 0.8 | 10.3 | 91.7 | 14.40 | 3500 |

| Drill and endmill are recommended. Suitable for cutting general steel(HRC<48),grey cast iron, stainless steel and heat resistant alloy. | ||||||

| GH10.2 | YL10.2 | 0.6 | 10.2 | 92.3 | 14.30 | 3800 |

| Drill and endmill are recommended. Especially suitable for cutting stainless steel, heat resistant alloy, cast iron. | ||||||

| øD | Tol.of Length (+0~+5) | ød | TKø | Pitch ( ±0.5°) | a | ||

| P | Tol. | ||||||

| 3 | 330 | 0.40 | 1.70 | 16.32 | -0.32 | +0.33 | 0.15 |

| 4 | 330 | 0.60 | 2.20 | 21.77 | -0.43 | +0.45 | 0.15 |

| 5 | 330 | 0.70 | 2.60 | 27.21 | -0.54 | +0.56 | 0.15 |

| 6 | 330 | 0.70 | 2.60 | 32.65 | -0.65 | +0.67 | 0.15 |

| 7 | 330 | 1.00 | 3.70 | 38.09 | -0.76 | +0.78 | 0.15 |

| 8 | 330 | 1.00 | 4.00 | 43.53 | -0.86 | +0.89 | 0.15 |

| 9 | 330 | 1.40 | 4.80 | 48.97 | -0.97 | +1.00 | 0.20 |

| 10 | 330 | 1.40 | 4.80 | 54.41 | -1.08 | +1.11 | 0.20 |

| 11 | 330 | 1.40 | 5.30 | 59.86 | -1.19 | +1.22 | 0.30 |

| 12 | 330 | 1.40 | 6.25 | 65.30 | -1.30 | +1.34 | 0.30 |

| 13 | 330 | 1.75 | 6.50 | 70.74 | -1.40 | +1.45 | 0.37 |

| 14 | 330 | 1.75 | 7.10 | 76.18 | -1.51 | +1.56 | 0.40 |

| 15 | 330 | 1.75 | 7.70 | 81.62 | -1.62 | +1.67 | 0.40 |

| 16 | 330 | 1.75 | 8.30 | 87.06 | -1.73 | +1.78 | 0.40 |

| 17 | 330 | 1.75 | 8.90 | 92.50 | -1.84 | +1.89 | 0.45 |

| 18 | 330 | 2.00 | 9.55 | 97.95 | -1.94 | +2.00 | 0.50 |

| 19 | 330 | 2.00 | 10.10 | 103.39 | -2.05 | +2.12 | 0.50 |

| 20 | 330 | 2.00 | 10.40 | 108.83 | -2.16 | +2.23 | 0.50 |

| 21 | 330 | 2.00 | 11.15 | 114.27 | -2.27 | +2.34 | 0.50 |

| 22 | 330 | 2.00 | 11.60 | 119.71 | -2.38 | +2.45 | 0.50 |

| 23 | 330 | 2.00 | 12.20 | 125.15 | -2.48 | +2.56 | 0.50 |

| 24 | 330 | 2.00 | 12.80 | 130.59 | -2.59 | +2.67 | 0.50 |

| 25 | 330 | 2.00 | 13.30 | 136.03 | -2.70 | +2.78 | 0.50 |

| GH Standard | Unground ØD(mm) | Ground ØD(mm) | ||

| Range | Tol. | Range | Tol. | |

| 3≤øD≤6 | +0.60 ~+1.00 | 3≤øD≤25 | h6 | |

| 6<øD≤24 | +0.70 ~+1.10 | |||

| øD=25 | +0.80 ~+1.20 | |||

| Ød (mm) | TKø (mm) | |||

| Range | Tol. | Range | Tol. | |

| 0.40≤ød≤0.90 | ±0.10 | TKø≤4.00 | +0~-0.40 | |

| 0.90<ød≤1.70 | ±0.15 | 4.00 | +0~-0.60 | |

| ød=1.75 | ±0.20 | 5.00 | +0~-0.80 | |

| ød=2.00 | ±0.25 | 10.10 | +0~-1.00 | |

| øD | Tol.of Length (+0~+5) | ød | TKø | Pitch ( ±0.5°) | a | ||

| P | Tol. | ||||||

| 6 | 330 | 0.50 | 2.20 | 22.46 | -0.39 | +0.40 | 0.15 |

| 8 | 330 | 0.65 | 2.70 | 29.95 | -0.53 | +0.54 | 0.15 |

| 10 | 330 | 0.80 | 3.50 | 37.44 | -0.66 | +0.67 | 0.20 |

| 12 | 330 | 0.90 | 4.20 | 44.93 | -0.79 | +0.80 | 0.30 |

| 14 | 330 | 1.00 | 4.70 | 52.42 | -0.92 | +0.94 | 0.40 |

| 16 | 330 | 1.20 | 5.50 | 59.90 | -1.05 | +1.07 | 0.40 |

| 18 | 330 | 1.40 | 6.30 | 67.39 | -1.18 | +1.21 | 0.50 |

| 20 | 330 | 1.50 | 7.10 | 74.88 | -1.31 | +1.34 | 0.50 |

| GH Standard | Unground ØD(mm) | Ground ØD(mm) | ||

| Range | Tol. | Range | Tol. | |

| 6≤øD≤20 | +1.10 ~+1.50 | 6≤øD≤20 | h6 | |

| Ød (mm) | TKø (mm) | |||

| Range | Tol. | Range | Tol. | |

| 0.40≤ød≤0.60 | ±0.10 | TKø≤2.20 | +0~-0.40 | |

| 0.60<ød≤0.90 | ±0.15 | 2.20 | +0~-0.60 | |

| 0.90<ød≤1.20 | ±0.20 | 2.70 | +0~-0.80 | |

| 1.20<ød≤1.50 | ±0.25 | TKø=7.10 | +0~-1.00 | |

Delivery time

For samples: 5-7 daysFor formal orders:10 -15 days

Payment

T/T, Western Union, PayPal, Money Gram, etc.

Payment≤1000 dollars, 100% in advance. Payment≥10000 dollars, 30% T/T in advance ,balance before shipment.

Packing

Standard carton

Shipment

DHL, FedEx, TNT, UPS, EMS, etc.

Any port in China.